In the fast-paced world of printing, efficiency is paramount. Press owners and operators are constantly seeking ways to streamline workflows and boost output. One area ripe for improvement is the curing process. Traditional methods can often be a bottleneck, slowing down production lines and impacting overall profitability. This is where the innovative power of LED UV curing systems comes into play. Retrofitting existing printing presses with these advanced systems offers a compelling solution to dramatically reduce curing times, enhance print quality, and open up new application possibilities.

The Limitations of Conventional Curing

For decades, printers have relied on various curing technologies, including mercury vapor lamps. While these systems have served the industry well, they come with inherent drawbacks. Mercury lamps require a warm-up period, consume significant energy, and generate substantial heat. This heat can be detrimental to sensitive substrates, leading to warping or delamination. Furthermore, the curing output of mercury lamps can degrade over time, necessitating frequent bulb replacements and calibration. The slow curing speed often dictates slower press speeds, limiting the maximum output of the press. This directly impacts throughput and the ability to meet tight deadlines.

Introducing LED UV Curing: A Paradigm Shift

Light Emitting Diode (LED) UV curing represents a significant leap forward. Unlike traditional mercury lamps, LED systems offer instant on/off capabilities, eliminating warm-up and cool-down times. They emit a highly specific wavelength of UV light, which is precisely matched to the absorption peaks of UV-curable inks, coatings, and adhesives. This targeted energy delivery results in faster, more efficient curing.

The benefits extend beyond just speed. LED UV systems are remarkably energy-efficient, consuming a fraction of the power of their mercury counterparts. They also generate minimal heat, making them ideal for printing on a wide range of heat-sensitive materials. Crucially, LED lamps boast an exceptionally long lifespan, often exceeding 20,000 hours, which translates to reduced maintenance costs and less downtime.

The Power of Retrofitting: Modernizing Existing Assets

The prospect of investing in entirely new printing presses can be daunting for many businesses. Fortunately, retrofitting existing machinery with LED UV curing systems presents a more accessible and cost-effective path to modernization. This strategy allows printers to leverage their current press investments while gaining the advantages of cutting-edge curing technology.

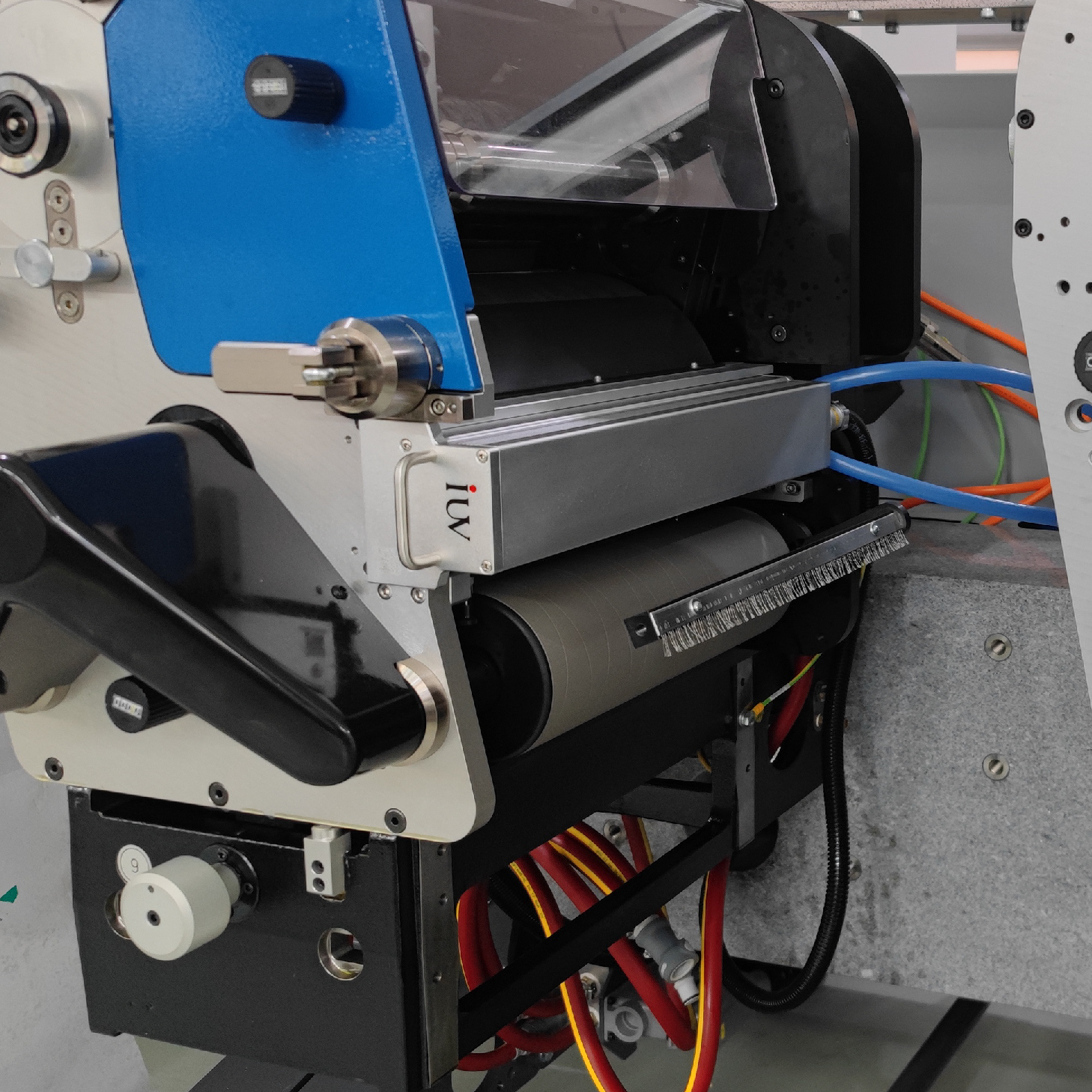

Retrofitting involves integrating LED UV lamp heads into the existing press structure. This can be done at various points in the printing process, depending on the specific application and desired outcome. For narrow web label presses, retrofitting can occur between printing stations, after the last printing unit, or in a finishing/converting line. Similarly, in sheetfed and web offset printing, LED UV units can be installed in the delivery section or at inter-station points.

Retrofit Strategies for Specific Print Sectors

1. Narrow Web Flexographic Printing:

For label and packaging printers, narrow web flexo presses are workhorses. Retrofitting these presses with LED UV systems is a popular and highly effective strategy.

- Inter-station Curing: Placing LED UV units between flexographic printing stations allows for immediate curing of inks. This enables printers to achieve faster press speeds without ink trapping or smearing issues. It also facilitates the use of a wider range of ink colors and special effects, as each layer can be fully cured before the next is applied. This is particularly beneficial for multi-layer labels or intricate graphics.

- End-of-Press Curing: Installing LED UV lamps at the end of the printing line provides a final cure for inks and coatings. This ensures complete drying and optimal adhesion, preparing the printed material for immediate rewinding or further converting processes. It significantly reduces the need for extensive drying times or separate curing lines.

- Specialty Coatings and Varnishes: LED UV retrofits enable the application of high-gloss, matte, or textured varnishes with rapid curing. This enhances the visual appeal and tactile qualities of labels without adding significant time to the production run.

2. Sheetfed Offset Printing:

Sheetfed offset printers can also reap substantial benefits from LED UV retrofits, especially for shorter runs and faster turnaround times.

- Delivery Section Retrofits: Installing LED UV units in the delivery section of a sheetfed offset press allows for immediate curing of the entire sheet as it exits the press. This eliminates the need for long cooling towers or stacking delays. Printed sheets are ready for handling, cutting, or folding almost instantly, dramatically accelerating post-press operations.

- Inter-station Curing (Specialty Applications): While less common in standard offset, inter-station LED UV can be employed for specialized applications requiring immediate curing of specific ink layers or coatings, such as overprint varnishes that need to be fully set before the sheet enters the next unit.

3. Web Offset Printing:

For continuous web offset printing, particularly in commercial and publication printing, retrofitting offers significant advantages in throughput.

- Final Curing: Similar to narrow web, LED UV systems can be integrated at the end of the web path for a final cure. This allows for immediate cutting, folding, or rewinding of the printed web, eliminating waiting periods.

- Inline Finishing: By enabling rapid curing, LED UV systems facilitate inline finishing processes. This means that booklets can be stitched, or other finishing operations can occur immediately after printing, without the need for intermediate drying or handling steps.

Key Considerations for a Successful Retrofit

When planning an LED UV retrofit, several factors warrant careful attention to ensure optimal performance and integration.

- Press Compatibility and Space: Assess the available space on your press for mounting LED UV lamp heads. Different press designs will have varying constraints. Consulting with equipment manufacturers is crucial to determine the best placement and mounting solutions.

- Power Requirements: LED UV systems have specific power demands. Ensure your existing electrical infrastructure can support the new installations. This might involve upgrades to power distribution panels or dedicated circuits.

- Ink and Coating Selection: While LED UV systems cure efficiently, it’s important to use inks and coatings specifically formulated for LED UV curing. These formulations are designed to react optimally under the specific wavelengths emitted by LED lamps. Working with ink suppliers is essential to select the right products for your chosen LED system.

- Exhaust and Ventilation: Although LED UV systems generate less heat than mercury lamps, proper ventilation is still important, especially in enclosed press areas. Ensure adequate airflow to manage any residual heat and to dissipate potential ozone byproducts, though ozone generation is typically much lower with LEDs.

- Curing Wavelength and Intensity: LED UV systems are available with different peak wavelengths (e.g., 365nm, 385nm, 395nm, 405nm). The choice of wavelength depends on the specific inks and coatings being used. The intensity of the UV output (measured in W/cm²) also plays a critical role in curing speed. A thorough analysis of your application requirements will guide the selection of the appropriate LED system.

- Integration with Existing Controls: The new LED UV system needs to be integrated with the press’s control system for seamless operation. This allows for synchronized activation and deactivation of the lamps with the press speed, ensuring efficient curing without waste.

The Economic and Operational Advantages

The decision to retrofit with LED UV systems is often driven by tangible economic and operational benefits:

- Reduced Curing Times: This is the primary advantage. Faster curing means faster press speeds, leading to higher throughput and increased productivity.

- Lower Energy Consumption: LED systems are significantly more energy-efficient than traditional mercury lamps, resulting in lower electricity bills and a reduced carbon footprint.

- Reduced Downtime and Maintenance: The long lifespan of LED lamps minimizes the frequency of replacements and associated downtime. This translates to more consistent production and lower maintenance costs.

- Improved Print Quality: Precise wavelength control and efficient curing contribute to sharper details, better ink adhesion, and superior gloss or matte finishes.

- Expanded Substrate Capabilities: The low-heat emission of LED UV allows for printing on a wider variety of heat-sensitive materials, opening up new market opportunities for label and packaging printers.

- Environmental Benefits: Reduced energy consumption and the absence of mercury contribute to a more environmentally friendly printing process.

Conclusion: A Strategic Investment in the Future

Retrofitting existing printing presses with LED UV curing systems is a smart, strategic investment for any print business looking to enhance efficiency, improve quality, and remain competitive. Whether you operate narrow web flexographic, sheetfed offset, or web offset machinery, the advantages of faster curing times, lower operational costs, and expanded application capabilities are undeniable. By carefully planning and implementing these retrofit strategies, printers can unlock the full potential of their current assets and position themselves for sustained success in the evolving print landscape. Embracing this technology is not just about upgrading equipment; it’s about fundamentally improving your production process for a more profitable and sustainable future.