The landscape of printing is constantly evolving, driven by demands for faster production, higher quality, and, increasingly, sustainability. In this pursuit, UV LED curing technology has emerged as a transformative force, offering significant advantages over traditional mercury lamp curing systems. This is particularly true for label printing, flexographic printing, offset printing, and narrow web applications, where efficiency and performance are paramount.

The Limitations of Traditional UV Curing

For years, mercury vapor lamps have been the workhorse of UV curing in the printing industry. While they have served their purpose, they come with inherent drawbacks. These lamps consume a substantial amount of energy, a significant portion of which is converted into heat rather than usable UV light. This heat can negatively impact heat-sensitive substrates, leading to warping or shrinkage, and often requires extensive and energy-intensive cooling systems.

Furthermore, mercury lamps have a finite lifespan and degrade over time, meaning their UV output diminishes, affecting cure speeds and quality. Their warm-up and cool-down periods also contribute to production delays and wasted energy. Replacing mercury lamps is a recurring cost, and their disposal presents environmental challenges due to the presence of mercury.

Enter UV LED Curing: A Paradigm Shift

UV LED curing technology represents a significant leap forward. Instead of a broad spectrum of light from a heated filament, LEDs emit a narrow band of UV light at specific wavelengths. This targeted approach offers several compelling benefits for printing operations.

One of the most immediate advantages is energy efficiency. UV LEDs consume considerably less power compared to mercury lamps. They convert a much higher percentage of electrical energy into UV light, minimizing wasted heat. This translates directly into lower electricity bills, a crucial consideration for any print business aiming to optimize operational costs.

The Substrate Advantage: Handling Heat-Sensitive Materials

The reduced heat output of UV LED systems is a game-changer for printing on a variety of substrates. In narrow web printing, for example, where flexible films and thin papers are common, excessive heat from traditional lamps can cause dimensional instability. This can lead to registration issues and affect the final print quality. UV LED curing, with its localized and cooler application of UV energy, allows for printing on a broader range of materials without the risk of heat-induced distortion. This opens up new possibilities for product differentiation and market expansion.

Instant On/Off and Precise Control

Unlike mercury lamps that require warm-up and cool-down cycles, UV LEDs are instant on and off. This means they only consume energy when they are actively curing. This is incredibly beneficial for job changeovers and intermittent printing processes. There’s no waiting for lamps to reach optimal temperature or cool down before the next job starts. This feature boosts productivity and further enhances energy savings by eliminating idle energy consumption.

The ability to precisely control the intensity and wavelength of UV light emitted by LEDs also offers superior control over the curing process. This allows printers to fine-tune parameters for specific inks, coatings, and substrates, ensuring optimal cure depth, adhesion, and surface properties. This level of control is difficult to achieve with the broad-spectrum, less controllable output of mercury lamps.

Boosting Productivity and Quality in Label and Narrow Web Printing

For the label printing sector, and by extension narrow web printing applications, UV LED curing is particularly transformative. The ability to achieve faster cure speeds, even on challenging substrates, means higher press speeds are attainable. This directly impacts throughput and the ability to meet demanding production schedules.

Moreover, the consistent and precise UV output from LEDs ensures a thorough and uniform cure across the printed area. This leads to improved print quality, including enhanced gloss, better scratch and chemical resistance, and superior adhesion. For labels that need to withstand harsh environments or extensive handling, this level of cure integrity is non-negotiable.

Flexographic and Offset Printing: Embracing Efficiency

In flexographic printing, especially in narrow web applications, the benefits of UV LED curing are readily apparent. Flexo presses are often characterized by high speeds and the need for precise ink transfer and curing. UV LEDs can keep pace with these demands, ensuring rapid ink setting and preventing ink from migrating or smudging. The reduced heat also protects the anilox rolls and other sensitive components of the flexo press.

For offset printing, particularly sheetfed and web offset operations, UV LED curing offers a path to faster turnaround times and reduced energy consumption. The ability to print and cure multiple colors in a single pass, without the thermal load of mercury lamps, can significantly streamline the printing process. This is especially valuable for commercial printers looking to offer a wider range of finishes and faster delivery times.

Durability and Longevity: A Long-Term Investment

UV LED systems boast a significantly longer operational lifespan than mercury lamps, often lasting tens of thousands of hours. This translates into reduced maintenance downtime and lower recurring replacement costs. While the initial investment in UV LED technology may be higher, the long-term savings in energy, consumables, and maintenance make it a financially sound decision.

The robust nature of LED technology also means they are less susceptible to vibrations and physical shock, making them ideal for the demanding environment of a printing press.

Environmental Considerations: A Greener Choice

Beyond the operational efficiencies, UV LED curing aligns with the growing imperative for sustainable printing practices. The substantial reduction in energy consumption directly lowers a print shop’s carbon footprint. Furthermore, the absence of mercury in LED systems eliminates the hazardous waste associated with traditional lamps, contributing to a safer and more environmentally responsible operation. This focus on sustainability is increasingly important for print businesses looking to appeal to environmentally conscious clients and meet regulatory requirements.

Upgrading Your Print Line: Key Considerations

When considering an upgrade to UV LED curing for your print line, several factors warrant attention:

- Wavelength Compatibility: Ensure the LED system’s wavelengths match the specific UV inks and coatings you use. Common wavelengths include 365nm, 385nm, 395nm, and 405nm.

- Power Density: Assess the required power density for your application to achieve the desired cure speed and quality. Higher power density generally means faster curing.

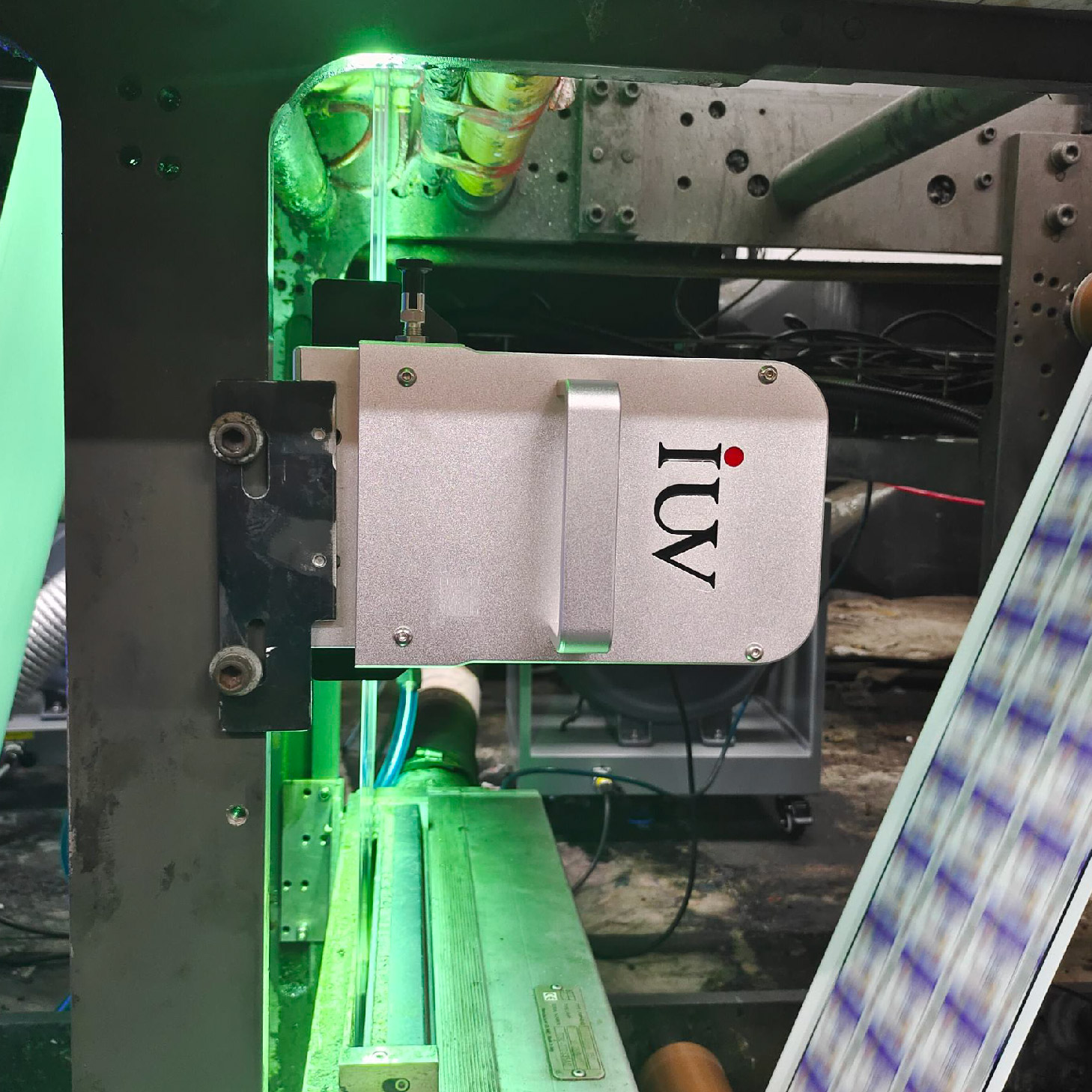

- Integration and Retrofitting: Determine how the LED system will integrate with your existing press. Many systems are designed for easy retrofitting, but careful planning is necessary.

- Cooling Requirements: While LEDs generate less heat, some systems still require air or water cooling, especially at higher power outputs. Understand the cooling infrastructure needed.

- Ink and Coating Formulations: Work with your ink and coating suppliers to ensure their products are optimized for UV LED curing. Many new formulations are specifically designed for this technology.

- ROI Analysis: Conduct a thorough return on investment analysis that factors in energy savings, reduced maintenance, increased productivity, and potential for new business opportunities.

The Future is Bright with UV LED

The transition to UV LED curing technology is not just an upgrade; it’s a strategic investment in the future of your printing operation. By embracing energy efficiency, enhanced control, superior substrate handling, and a commitment to sustainability, print lines equipped with UV LED solutions are positioned for greater productivity, improved quality, and a stronger competitive edge in the evolving print market. The move towards smarter, more efficient curing methods is undeniable, and UV LED technology stands at the forefront of this revolution.