Flexographic printing, a versatile and widely used printing method, has long been a staple in the packaging and label industries. Its adaptability and cost-effectiveness have made it a go-to for producing everything from intricate label designs to large-scale packaging materials. However, like many traditional printing processes, flexography has historically relied on energy-intensive and sometimes environmentally impactful curing methods.

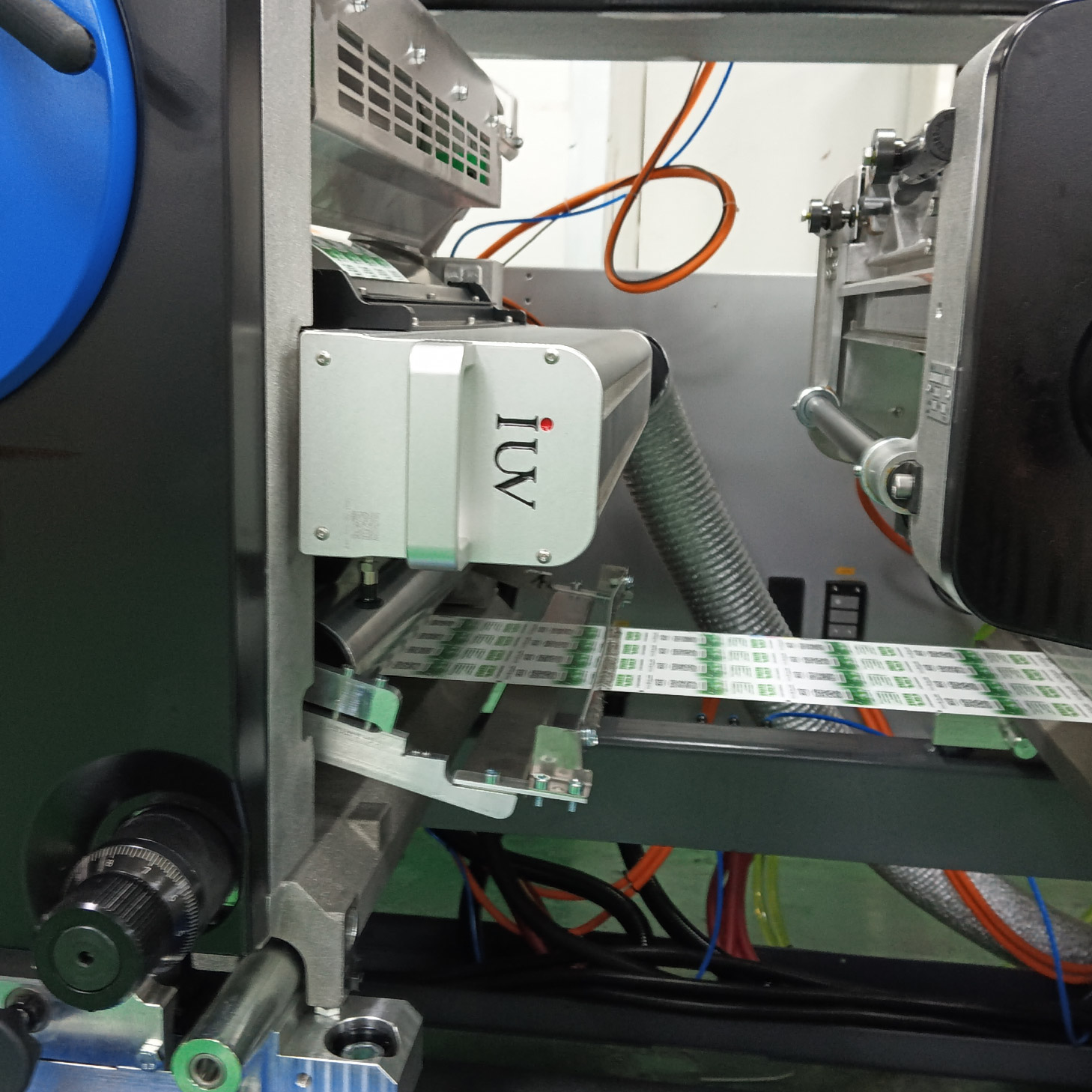

Enter UV LED curing technology. This innovative approach is revolutionizing flexographic printing, offering a potent combination of eco-friendliness and enhanced efficiency. For businesses operating within the narrow web printing sector, particularly those focused on labels and flexible packaging, understanding and adopting UV LED solutions is no longer just an option – it’s a strategic imperative for staying competitive and sustainable.

The Evolution of UV Curing in Flexography

For decades, UV curing has been a known quantity in the printing world. Traditional mercury vapor lamps have served the industry well, providing rapid drying times that are essential for high-speed printing operations. These lamps emit ultraviolet light, which initiates a photochemical reaction in UV-curable inks, causing them to instantly solidify, or “cure.” This process is highly beneficial for flexographic printing, as it allows for immediate handling of printed materials, reduces the need for large drying areas, and enables printing on a wide range of substrates, including heat-sensitive films.

However, traditional UV lamps come with several drawbacks. They generate significant heat, which can stress certain substrates and require robust cooling systems. They also consume a considerable amount of energy and have a limited lifespan, necessitating frequent replacement. Furthermore, mercury, a component in many traditional lamps, poses environmental concerns.

The UV LED Advantage: A Greener, More Efficient Future

UV LED (Light Emitting Diode) curing represents a significant leap forward. Instead of broad-spectrum light emitted by mercury lamps, UV LEDs emit light at specific wavelengths. This targeted approach offers a cascade of benefits for flexographic printers:

- Energy Efficiency: UV LEDs consume dramatically less energy compared to traditional UV lamps. This translates directly into lower electricity bills and a reduced carbon footprint, a crucial consideration for environmentally conscious businesses.

- Instant On/Off and Precise Control: LEDs can be switched on and off instantaneously. This means energy is only used when printing is actually occurring, further enhancing efficiency. It also allows for precise control over the curing process, optimizing for different inks and substrates.

- Lower Heat Emission: While UV LEDs do produce some heat, it is significantly less than that generated by mercury lamps. This allows for printing on a wider array of heat-sensitive materials, such as thin films and some plastics, without causing deformation or damage.

- Longer Lifespan: UV LED systems have a considerably longer operational life than traditional UV lamps, often lasting tens of thousands of hours. This reduces maintenance costs and the frequency of lamp replacements, minimizing downtime and waste.

- Environmental Benefits: The absence of mercury in UV LED technology aligns with growing environmental regulations and corporate sustainability goals. This makes it a much cleaner and safer curing solution.

- Improved Curing Performance: Specific wavelengths emitted by LEDs can be optimized for particular UV-curable ink formulations, leading to superior adhesion, scratch resistance, and overall print quality.

Navigating the Narrow Web: Label Printing and Beyond

The narrow web printing sector, which primarily focuses on labels and flexible packaging, is where UV LED technology is making some of its most profound impacts. The demands of this market – high speeds, intricate graphics, diverse substrates, and a constant push for cost reduction and sustainability – align perfectly with the advantages offered by UV LED curing.

For label printers, the ability to achieve consistent, high-quality results on a variety of materials is paramount. Whether printing on pressure-sensitive labels for food and beverage, durable labels for industrial applications, or shrink sleeves, UV LED curing ensures rapid drying and excellent ink adhesion. This is particularly important for applications requiring high rub and chemical resistance, such as those found in the automotive or cosmetic industries.

The precise control offered by UV LED systems also benefits label printers dealing with complex designs and fine details. It ensures sharp dot definition and vibrant color reproduction, critical for brand recognition and product appeal on the shelf.

Flexographic Printing and UV LED Ink Technologies

The synergy between UV LED curing and advanced ink formulations is key to unlocking the full potential of this technology. UV-curable inks for flexography have been specifically developed to react to the specific wavelengths emitted by LEDs. These inks offer:

- Rapid Cure Speed: Designed for high-speed printing lines, ensuring that inks cure almost instantaneously upon exposure to UV LED light.

- Excellent Adhesion: Formulated to bond effectively to a wide range of substrates, from porous paper to non-porous films like BOPP, PET, and PVC.

- Durability: Providing superior resistance to abrasion, scratching, chemicals, and weathering, meeting the demanding performance requirements of various end-use applications.

- Low Migration: Crucial for food packaging applications, modern UV LED inks are formulated to minimize migration of components from the ink into the packaged product, ensuring food safety compliance.

- Color Vibrancy and Stability: Delivering bright, consistent colors that maintain their integrity over time.

The development of specialized UV LED inks has been instrumental in the widespread adoption of this curing technology. Printers can now choose from a broad spectrum of inks – including opaque whites, vibrant process colors, metallic effects, and specialty finishes – all optimized for LED curing.

Integrating UV LED into Your Flexographic Workflow

Adopting UV LED curing technology in a flexographic printing operation involves careful consideration and planning. Here are some key aspects to evaluate:

- Equipment Compatibility: Newer flexographic presses are often designed with UV LED curing systems integrated from the outset. However, retrofitting existing presses is also a viable option. This requires assessing the available space, power requirements, and compatibility with the press’s speed and substrate handling capabilities.

- Wavelength Selection: UV LEDs are available in different wavelength ranges. The most common for UV curing are around 365 nm, 385 nm, 395 nm, and 405 nm. The choice of wavelength will depend on the specific inks being used and the desired curing performance. Your ink supplier can provide guidance on the optimal wavelength for their products.

- Irradiance and Dose: Understanding irradiance (the power of the UV light per unit area) and UV dose (the total amount of UV energy delivered) is critical for achieving proper curing. Higher irradiance generally leads to faster cure speeds. The required dose will vary based on ink type, substrate, and desired performance.

- Substrate Considerations: While UV LED technology is less heat-intensive, it’s still important to consider the substrate’s thermal stability, especially at high printing speeds. Testing is always recommended.

- Maintenance and Support: While UV LED systems require less maintenance than traditional UV lamps, they still need occasional cleaning and checks. It’s beneficial to work with reputable manufacturers that offer good technical support and readily available replacement parts.

- Cost-Benefit Analysis: While the initial investment in UV LED curing equipment may be higher than for traditional systems, the long-term savings in energy consumption, reduced maintenance, and fewer consumables often result in a favorable return on investment.

The Future is Bright: Continued Innovation

The evolution of UV LED technology in flexographic printing is far from over. Ongoing research and development are focusing on:

- Higher Power and Efficiency: Developing LEDs with even greater power output and improved energy efficiency.

- Broader Wavelength Flexibility: Offering greater choice in wavelengths to accommodate an even wider range of ink chemistries and specialty applications.

- Advanced Control Systems: Integrating smarter control systems that optimize curing parameters in real-time, further enhancing consistency and efficiency.

- New Ink Formulations: Continuously innovating ink formulations to meet emerging market demands for sustainability, functionality, and performance.

For businesses in the narrow web printing sector, embracing UV LED curing solutions is a proactive step towards a more sustainable, efficient, and profitable future. It allows for superior print quality, expanded application possibilities, and a significantly reduced environmental impact, positioning printers for success in an increasingly demanding global market.