The print industry is constantly seeking ways to improve efficiency and reduce operational costs. For narrow-web and offset printing businesses, energy consumption is a significant factor. Traditional UV curing systems, while effective, can be power-hungry. The adoption of LED-based UV curing technology presents a compelling solution for energy optimization. This shift is not just about saving money; it’s about enhancing print quality, improving workflow, and embracing a more sustainable printing future.

Understanding UV Curing in Print

UV curing uses ultraviolet light to instantly dry or “cure” inks, coatings, and adhesives. This process is essential in many printing applications, especially where high durability, gloss, or specific functional properties are required. In narrow-web printing, used for labels and flexible packaging, and in offset printing, commonly used for commercial print and folding cartons, efficient curing is paramount. It allows for faster production speeds and the ability to print on a wider range of substrates, including heat-sensitive materials.

Traditional UV curing lamps, like mercury vapor lamps, generate a broad spectrum of light and considerable heat. While they have been the standard for decades, their energy inefficiency and the heat they produce can be drawbacks. This heat can warp thinner substrates, limit press speed, and require extensive ventilation and cooling systems, all contributing to higher energy bills.

The Rise of LED UV Curing

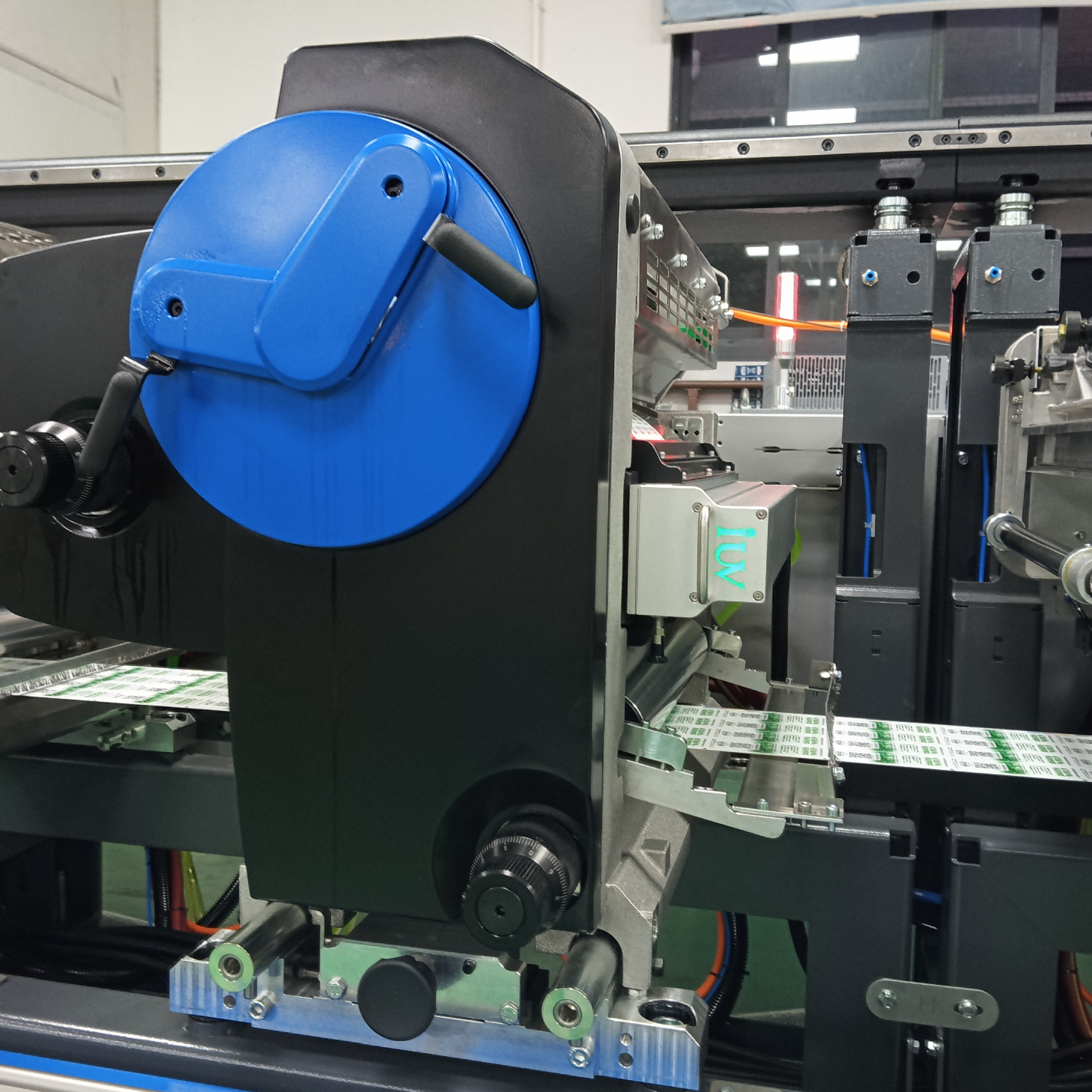

Light Emitting Diode (LED) UV curing technology offers a fundamentally different approach. Instead of a broad spectrum lamp, LEDs emit light within very narrow wavelength bands. This targeted emission means less wasted energy. Furthermore, LEDs operate at much lower temperatures than traditional lamps. This significant reduction in heat output has profound implications for printing operations.

The energy efficiency of LED UV systems is a primary driver for their adoption. They consume considerably less electricity per unit of UV output compared to mercury lamps. This translates directly into lower operating costs. Additionally, LED lamps have a much longer lifespan, often tens of thousands of hours, compared to a few thousand hours for mercury lamps. This reduces downtime for lamp replacement and associated maintenance costs.

Energy Optimization Strategies for Narrow-Web Presses

In the narrow-web sector, where space is often at a premium and substrate versatility is key, LED UV curing brings distinct advantages. Many label printers handle a variety of materials, from paper to films. The low heat output of LEDs means less risk of substrate distortion or shrinkage, allowing for more consistent print quality across different stock types.

Implementing LED UV curing on a narrow-web press can lead to significant energy savings. Because LEDs only emit the required UV wavelengths, they are inherently more efficient. They also reach full power instantly, eliminating warm-up times associated with mercury lamps. This “on-demand” nature means energy is only consumed when the lamp is actually curing.

Consider a label printer running multiple jobs throughout the day. With traditional lamps, they might keep the lamps on between short runs, consuming energy unnecessarily. LEDs can be switched on and off instantly with the press, further enhancing energy savings. The reduced heat also means less demand on the press’s cooling systems, which can be substantial energy consumers themselves.

Energy Optimization Strategies for Offset Presses

Offset printing, particularly in commercial and packaging applications, also benefits immensely from LED UV technology. For shops running sheetfed offset presses, the ability to cure inks and coatings instantly opens up new possibilities. The reduced heat output is critical when printing on thin paper stocks or heat-sensitive packaging materials.

Energy optimization in offset printing with LEDs involves several aspects. Firstly, the direct energy savings from the lamps themselves. Secondly, the reduced need for extensive inter-station cooling. Many offset presses rely on sophisticated cooling systems to manage the heat generated by both the printing process and the curing units. By reducing the heat load from the curing lamps, the demand on these cooling systems decreases, leading to further energy savings.

Furthermore, the instant on/off capability of LEDs means that energy is not wasted during makeready or short breaks. This is particularly relevant in shops that frequently change jobs. The consistent curing performance of LEDs also contributes to reduced waste. When inks and coatings cure properly and quickly, there are fewer instances of smudging, scratching, or poor adhesion, which can lead to rejected prints.

Beyond Energy: Additional Benefits of LED UV

The advantages of LED UV curing extend beyond just energy savings. The consistency of the UV output from LEDs ensures reliable curing performance, job after job. This consistency is crucial for maintaining high print quality and predictable results.

Another significant benefit is the environmental aspect. Reduced energy consumption directly translates to a smaller carbon footprint for the print shop. Furthermore, many LED UV systems do not require the hazardous materials found in mercury lamps, simplifying disposal and contributing to a safer working environment.

The spectral output of LEDs can be precisely controlled, allowing printers to match specific ink and coating chemistries for optimal performance. This precision can lead to improved print characteristics, such as enhanced gloss, better scratch resistance, and faster cure speeds, even at lower energy inputs.

Implementing LED UV Curing: Key Considerations

When considering the transition to LED UV curing, print shops should evaluate their current setup and future needs. The initial investment in LED systems can be higher than traditional UV lamps, but the long-term savings in energy, consumables, and maintenance often provide a compelling return on investment.

It is important to work with reputable equipment manufacturers who understand the specific requirements of narrow-web and offset printing. They can help assess the optimal LED configuration for your press, considering factors like press speed, ink/coating types, and substrate materials. Understanding the spectral output of the LEDs and ensuring compatibility with your chosen inks and coatings is crucial for successful implementation.

Furthermore, staff training is essential. While LED systems are generally simpler to operate and maintain than mercury lamps, proper understanding of their capabilities and limitations will maximize their benefits.

The Future is Bright (and Energy Efficient)

The move towards LED UV curing represents a significant evolution in printing technology. For narrow-web and offset print shops, it offers a tangible path to substantial energy optimization, reduced operating costs, and improved print quality. As the technology continues to advance, its adoption is expected to accelerate, driven by the clear economic and environmental advantages. Embracing LED UV curing is not just a technological upgrade; it’s a strategic investment in the future of efficient and sustainable printing.